Summer in the Appalachian Highlands brings a distinct set of weather patterns that can test the limits of any residential cooling system. In Bristol, VA, the combination of soaring daytime temperatures and thick, heavy humidity means air conditioners must work overtime to keep indoor environments comfortable. This constant demand places significant stress on mechanical components, leading to wear and tear that often results in system failures during the hottest weeks of the year. Homeowners frequently encounter specific issues driven by these local environmental factors, ranging from drainage blockages to electrical burnouts. Understanding the nature of these common problems is the first step toward maintaining a reliable system and avoiding the discomfort of a breakdown in the middle of July.

Managing Humidity and Drainage Issues in Southwest Virginia

One of the primary functions of an air conditioner is to dehumidify the air as it cools it; a task that is particularly critical in Bristol’s humid climate. As warm air passes over the cold evaporator coils, moisture condenses into water and drains away from the unit. However, the sheer volume of water produced during peak humidity can overwhelm the drainage system if it is not maintained correctly. Algae and mold thrive in these damp, dark environments and can quickly form sludge that blocks the condensate drain line. When this line becomes obstructed, water has nowhere to go but back into the home, potentially causing water damage to ceilings, floors, and drywall.

Furthermore, modern air conditioning systems are equipped with safety float switches designed to detect these backups. When the drain pan fills with water due to a clog, the switch trips and shuts off the entire system to prevent an overflow. Homeowners often mistake this safety shutdown for a catastrophic mechanical failure because the thermostat goes blank or the unit simply refuses to turn on. Clearing these blockages requires more than just pouring bleach down the line; it often necessitates high pressure flushing or vacuuming to remove the biological growth completely. If you find water pooling around your indoor unit or your system shuts off unexpectedly during humid weather, professional AC Repair Bristol VA is often required to clear the lines and verify that the drainage slope is correct to prevent future stagnation.

The Consequences of Frozen Evaporator Coils

A frozen evaporator coil is a paradoxical problem where the air conditioner is working so hard that it actually stops cooling. This issue usually stems from a restriction in airflow or a low refrigerant level, both of which prevent the coil from absorbing heat effectively. In Bristol homes, dirty air filters are the most frequent culprit; they block the warm air needed to keep the coil surface temperature above freezing. When the coil freezes, it becomes encased in a solid block of ice that completely blocks airflow through the air handler.

Continuing to run a system with a frozen coil places an immense strain on the compressor, which is the most expensive component of the AC unit. As the ice builds up, it can travel down the refrigerant lines to the outdoor unit, causing potential damage to the valves and pistons. Thawing the system takes time and requires turning the cooling function off completely, which leaves the home uncomfortable for hours. Preventing this requires diligent filter changes and regular monitoring of airflow to ensure heat exchange occurs efficiently.

Electrical Component Failures Due to Heat Stress

The electrical components within an air conditioning system are subject to intense heat and vibration every time the unit starts up. In Bristol, where systems may cycle on and off dozens of times a day to maintain temperature, capacitors and contactors are prone to failure. The capacitor acts like a battery that provides the initial jolt of electricity needed to start the compressor and fan motors. Over time, the chemical inside the capacitor can degrade due to heat exposure, causing it to swell or leak. When a capacitor fails, the motors may hum loudly but fail to spin, or they may struggle to start and overheat rapidly.

Contactors are the switches that control the flow of electricity to the compressor and outdoor fan. Every time the thermostat calls for cooling, the contactor pulls in to complete the electrical circuit. Over thousands of cycles, the metal contacts can become pitted and charred from the electrical arcing that occurs during engagement. This pitting increases electrical resistance, which can cause the voltage to drop and damage the compressor motor. Occasionally, a contactor can even become welded shut, causing the outdoor unit to run continuously even when the thermostat is satisfied or turned off. Identifying these electrical faults early through routine inspection can prevent a simple part replacement from turning into a major system overhaul.

Identifying Signs of Compressor Distress

The compressor is the heart of the air conditioning system, responsible for pumping refrigerant between the indoor and outdoor units. When electrical components like capacitors or contactors are failing, the compressor often bears the brunt of the stress. Homeowners might hear a phenomenon known as “hard starting,” where the outdoor unit shudders violently or makes a loud banging noise upon startup. This indicates that the compressor is struggling to overcome the internal pressure of the system to get moving.

If the compressor overheats, it has an internal thermal overload switch that will shut it down to prevent permanent damage. You might notice the outdoor fan running while the compressor is silent, resulting in warm air blowing from your vents. Repeated overheating events degrade the winding insulation inside the motor and contaminate the refrigerant oil. If your system is making grinding noises or tripping the circuit breaker repeatedly, it is a definitive sign that the compressor is in trouble. Immediate professional attention is necessary to determine if the issue is a supportive component or if the compressor itself needs to be replaced.

Airflow Restrictions and Ductwork Challenges

Even a mechanically sound air conditioner cannot perform effectively if the ductwork delivering the air is compromised. In many older Bristol homes, ductwork may be undersized, disconnected, or leaking, which drastically reduces the system’s efficiency. Leaks in the return ducts can pull in hot, dirty air from the attic or crawlspace, forcing the AC to work harder to cool it down. Conversely, leaks in the supply ducts allow expensive conditioned air to escape into unconditioned spaces before it ever reaches the living areas. This results in some rooms feeling stuffy and hot while the unit runs constantly to try and satisfy the thermostat.

Flexible ductwork is particularly susceptible to being crushed, kinked, or torn by activity in the attic or simple aging. A crushed duct acts like a kink in a garden hose; it physically stops the air from reaching its destination. This increases the static pressure within the system, which puts extra load on the blower motor and can lead to premature failure. Homeowners should ensure that vents are not blocked by furniture or heavy curtains, as this also restricts critical airflow. If you notice weak airflow from your registers or significant temperature differences between rooms, it likely points to a distribution problem that needs to be addressed by a ventilation expert.

The Importance of Regular System Maintenance

Many of the common problems faced by homeowners in the region can be mitigated or avoided entirely with proactive care. Neglect is the leading cause of premature HVAC failure; dirt buildup on coils reduces heat transfer, and worn belts or bearings create friction that destroys motors. A system that is clean and well-lubricated operates with less resistance, using less energy to provide the same level of cooling. Regular checks on refrigerant levels are also vital; even a small leak can reduce capacity and cause the evaporator coil to freeze.

Scheduling routine inspections allows a technician to catch small issues like a weak capacitor or a loose wire before they cause a breakdown on the hottest day of the year. This preventative approach extends the lifespan of the equipment and ensures it operates at peak efficiency. For residents dealing with an aging or problematic system, finding a reliable partner for AC Repair Bristol VA is essential for keeping the home cool and safe. Investing in the health of your air conditioner protects your property value and ensures your family remains comfortable regardless of the forecast.

SWVA Mechanical: Your Bristol, VA Cooling Experts

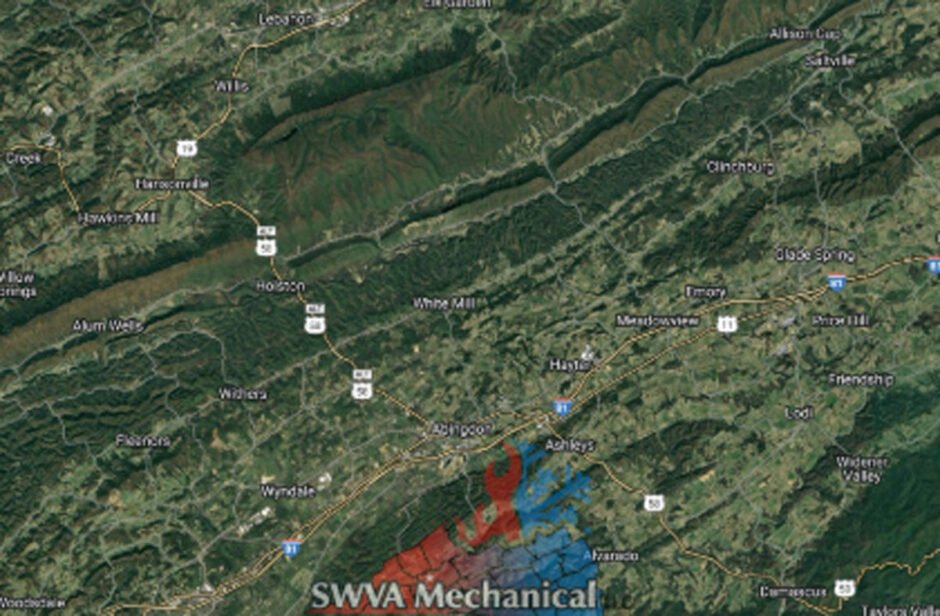

Dedicated Service for the Tri-Cities Area

SWVA Mechanical, located in nearby Lebanon, VA, is proud to provide top-tier heating and cooling services to homeowners throughout the Bristol community. We understand the specific challenges that our local climate imposes on air conditioning systems, and we are dedicated to keeping your home comfortable year-round. Our team of experienced and licensed technicians is trained to diagnose and resolve a wide range of AC issues, from complex electrical failures to routine maintenance needs. We prioritize your safety and satisfaction, ensuring that every repair is performed with integrity and precision.

Restoring Comfort and Efficiency

We specialize in breathing new life into struggling air conditioning systems. Whether you are dealing with a frozen coil, a clogged drain line, or a system that simply won’t turn on, SWVA Mechanical has the expertise to fix it right the first time. We offer honest assessments and reliable solutions to help you avoid unnecessary replacements and keep your energy bills in check. When summer heat strikes and your AC falters, trust the professional team at SWVA Mechanical to restore your comfort quickly. Contact us today for expert inspection and repair services in Bristol, VA.

Brian Street

SWVA Mechanical

72 W Main St APARTMENT 1, Lebanon, VA 24266

(276) 971-9514

https://swvamechanical.com/locations/abingdon-va/

brian@swvamechanical.com