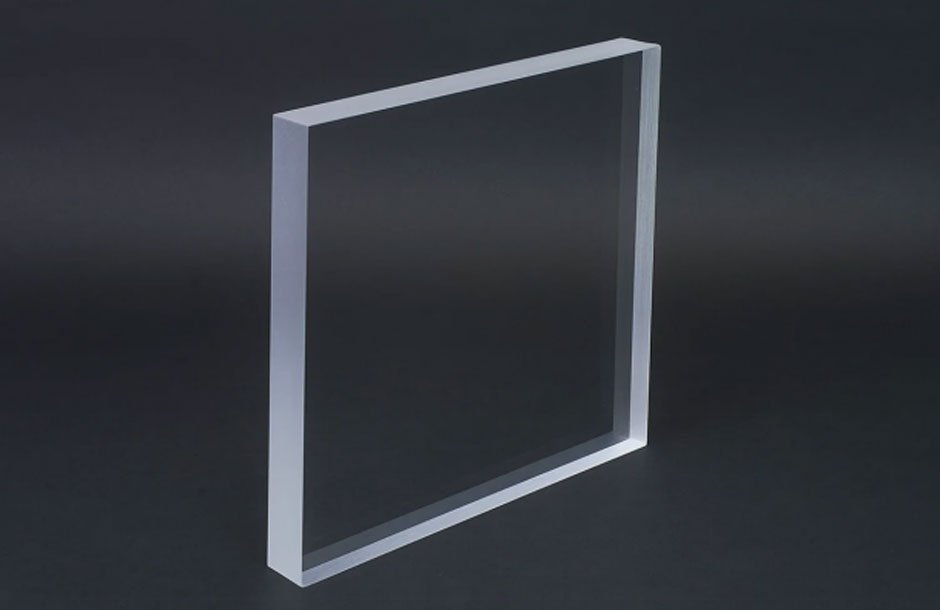

Plexiglass, also known as acrylic glass, has transformed from being a niche alternative to traditional glass into a mainstream material used across architecture, interior design, retail displays, and protective installations. Among its many available thicknesses, the 1/4 inch plexiglass sheet option stands out as a true sweet spot, balancing strength, weight, and workability. For anyone looking to source high-quality 1/4 inch plexiglass sheets, whether for a commercial build-out, creative project, or structural installation, understanding its performance characteristics, design flexibility, and sourcing considerations is critical.

In this expert guide, we will go beyond the basics to explore why this thickness has gained such a strong reputation, what applications truly benefit from it, and how to source the right sheets for maximum longevity and visual appeal.

Superior Strength-to-Weight Performance

One of the most compelling reasons designers and fabricators opt for 1/4 inch plexiglass sheets is the exceptional balance between durability and manageability. While thicker sheets naturally offer more impact resistance, they are heavier and harder to handle during fabrication and installation. The 1/4 inch thickness offers enough rigidity for most mid-scale applications while remaining light enough to be easily cut, drilled, and installed without specialized heavy-duty equipment.

This thickness can withstand moderate impact and pressure, making it suitable for high-contact environments without the brittleness of thinner sheets. Compared to traditional glass of the same thickness, plexiglass provides up to ten times the impact resistance, making it safer for environments where breakage risks are a concern, like retail counters, signage installations, and protective barriers.

Optical Clarity That Enhances Presentation

For projects where transparency and visual presentation are critical, 1/4 inch plexiglass sheets deliver exceptional clarity. High-grade sheets can transmit over 90% of visible light, which is on par with optically clear glass, but without the greenish tint that often affects thicker glass panels.

This makes them ideal for display cases, museum exhibits, and architectural features where crisp, distortion-free viewing is a must. For businesses showcasing products, such as jewelry, electronics, or baked goods, this optical quality ensures items are seen exactly as intended, with no color shifts or light scattering.

Precision in Fabrication and Customization

Professional fabricators favor 1/4 inch plexiglass for its adaptability in manufacturing processes. This thickness cuts cleanly on CNC routers, laser cutters, and even table saws with proper acrylic blades. It is thick enough to hold threaded inserts for hardware mounting, yet thin enough to be thermoformed into curves or shapes without excessive heating times.

Its workability also extends to finishing, edges can be flame polished to a glass-like shine, drilled for fasteners without cracking, and bonded seamlessly for multi-panel assemblies. This allows for highly customized installations such as architectural glazing, furniture accents, or branded displays that require both precision and durability.

Weather Resistance and Longevity

One of the core advantages of plexiglass over traditional glass is its resistance to environmental wear. The 1/4 inch thickness amplifies this resilience, providing robust protection against wind loads, rain, and temperature fluctuations. High-grade sheets, especially those with UV protection, resist yellowing and surface degradation even in prolonged outdoor exposure.

This durability makes them an excellent choice for outdoor signage, marine windows, patio enclosures, and greenhouse glazing. The thickness ensures enough structural stability to resist warping or flexing, while still being manageable to replace or adjust when needed.

Impact in Architectural and Interior Design

In contemporary architecture, 1/4 inch plexiglass sheets find applications in room dividers, balustrades, kitchen backsplashes, and office partitions. The thickness strikes a visual balance, it is substantial enough to appear intentional and high-quality but not so thick that it feels heavy or obstructive in modern, airy interiors.

Designers often use it in frosted, tinted, or colored variants to control privacy and lighting effects without sacrificing the clean lines of acrylic’s polished finish. Its light weight compared to glass makes it a cost-effective choice for large installations where support structure costs can be a concern.

Protective Barriers and Safety Installations

Since the rise in demand for protective barriers in high-traffic environments, 1/4 inch plexiglass has emerged as one of the most specified materials for this purpose. Its combination of shatter-resistance and sufficient thickness provides a reliable barrier without obstructing visibility or making spaces feel closed in.

In offices, retail counters, and public service points, this thickness maintains structural integrity against accidental bumps while still being easy to mount to countertops or frames. Additionally, if impact does occur, plexiglass will not shatter into sharp fragments like glass, significantly reducing injury risks.

Where to Source High-Quality Sheets

For professionals and DIY enthusiasts alike, sourcing quality plexiglass sheets is key to project success. Inferior materials can suffer from poor optical clarity, inconsistent thickness, or faster degradation under sunlight. Established marketplaces such as Fab Glass and Mirror and Glass Genius are known for offering premium-grade sheets with precise thickness control, consistent color, and proper UV protection options. This ensures your investment will perform well for years while meeting exacting project standards.

Maintenance Best Practices

Even though plexiglass is highly durable, proper care is essential to preserving its clarity and performance. For 1/4 inch sheets, cleaning with a microfiber cloth and a mild soap solution is sufficient for routine maintenance. Avoid ammonia-based cleaners, as these can cause micro-cracks over time.

In high-touch or outdoor installations, applying an anti-static cleaner can reduce dust buildup, while a scratch-resistant coating—available from certain manufacturers, can extend the sheet’s lifespan in demanding environments. For installations exposed to significant sunlight, UV-protected sheets combined with regular cleaning help maintain both appearance and structural integrity.

Cost Considerations and ROI

From a budget perspective, 1/4 inch plexiglass sheets strike an excellent balance between upfront cost and long-term value. While they are more expensive than thinner sheets, their durability and reduced risk of breakage often translate to lower replacement and maintenance costs over the product’s lifespan.

In commercial settings, the ROI extends beyond durability; better optical clarity enhances product presentation, while their safety profile reduces liability risks. For residential applications, their longevity and versatility often mean fewer material changes over the years, making them a smart investment.

The Strategic Choice for Demanding Projects

Ultimately, the 1/4 inch plexiglass sheet represents more than just a material; it is a design decision that impacts aesthetics, safety, and functionality. Architects, builders, and designers turn to this thickness because it consistently delivers across the most critical performance categories: clarity, strength, weather resistance, and fabrication flexibility.

Whether you are developing a modern office partition system, a high-end retail display, or a weather-resistant outdoor installation, this material offers the adaptability and professional finish that demanding projects require.

By choosing reputable suppliers, following expert fabrication methods, and maintaining the material properly, you ensure that your 1/4 inch plexiglass installations not only look stunning on day one but continue to perform for years. In the competitive world of design and construction, that reliability is exactly what sets successful projects apart.